Benefit

.It is a low-cost system. You can use it to measure, record and manage pressure int the cavity. As youknow, injection pressure is an critical parameter in the quality of product.

.Measuring the pressure of the resin injection is helpful for improving product quality.

.We can use the Injection Molding Cavity pressure monitoring system to do some experiments. This is helpful for optimizing the time and conditions of mold forming.

Adoption benefits

.Easily manage production quality through remote connection monitoring

.100% data access, providing complete production resume

.Available to set up molding condition data for mass production line in domestic factory

.Ejection pressure determine,protect the ejection pin and product

.With mechanical arm, you can choose bad products and prevent the production of continuous defective products

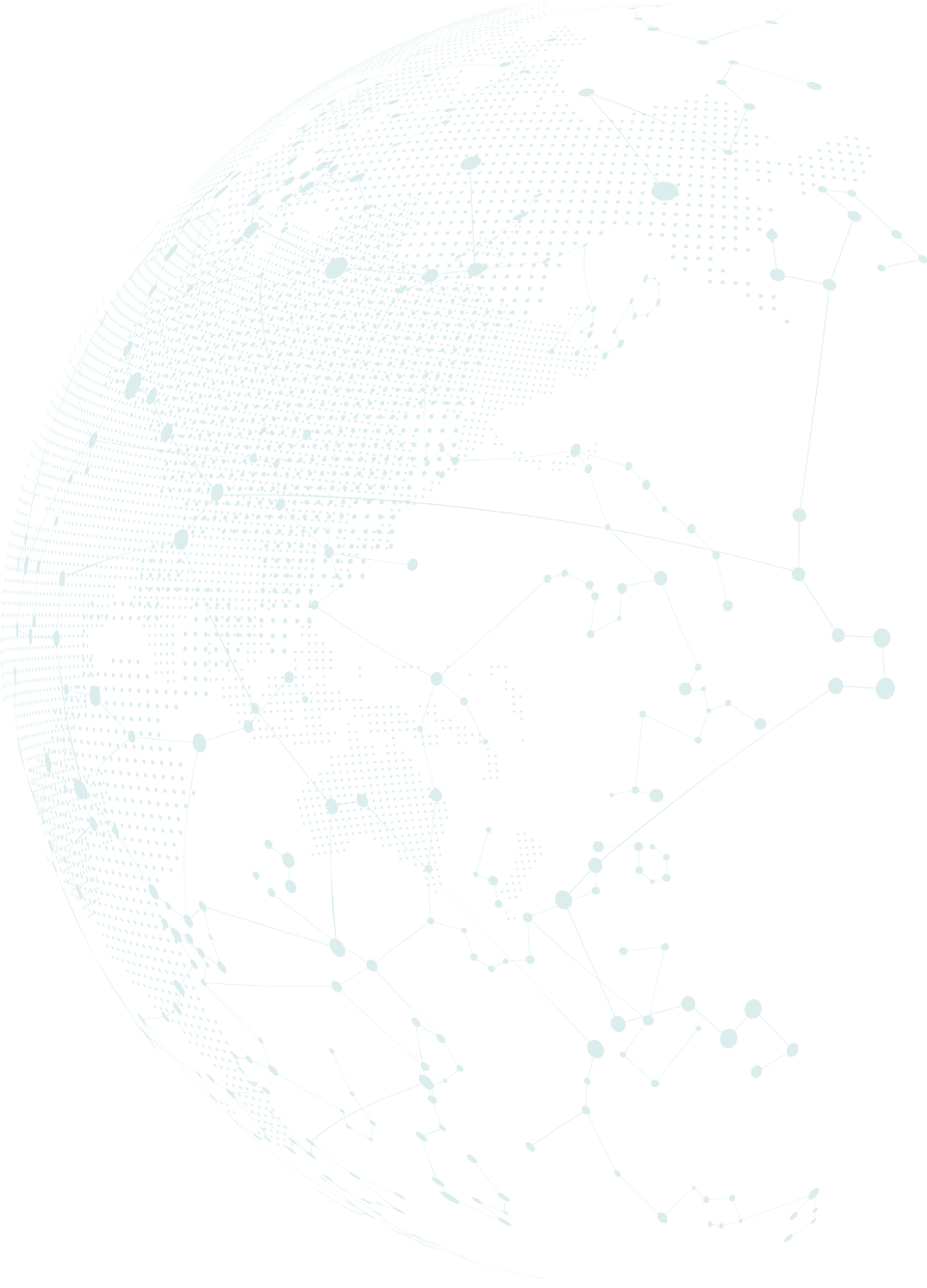

Standalone mode

TaskMaster Controller can automatically do quality judgment with PC,can be used with mechanical arm picking good or bad products,when the defective product too much can control the injection machine to stop production.

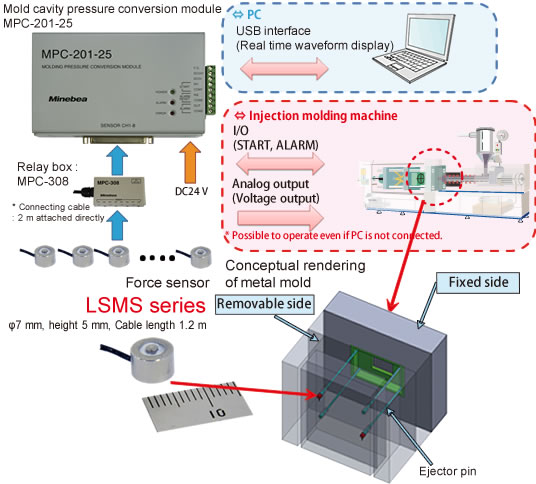

Network mode

TaskMaster controller can be connected to the factory through the Ethernet servo controller for full monitoring of the factory floor, and truly industrial 4.0.

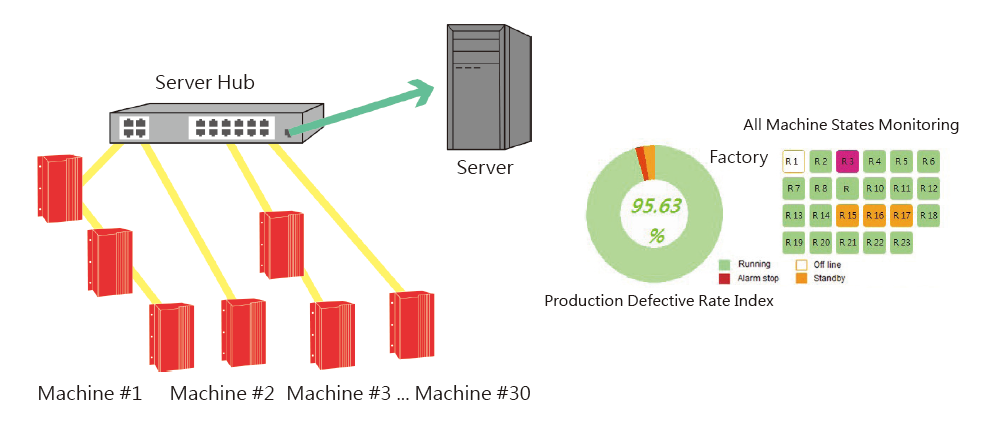

Cloud Mode

Through the handheld device or computer monitoring and parameter modification,easy to master production condition of different factory.

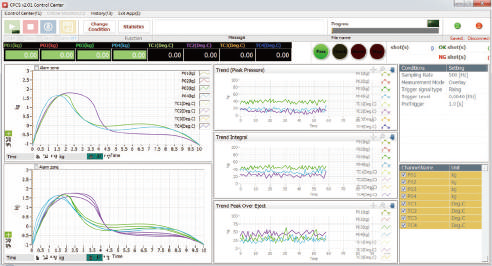

Basic software- TaskMaster IMC software

.Real-time graph display

.Overlay graph display

.“Trend”graphs can be displayed to calculate maximum/minimum values,mean values,and standard deviations for each channel.

.Provide the Defective Rate, temperature and production condition information

.Up to 3 alarm setting per channe

.Monitoring each machine of factory

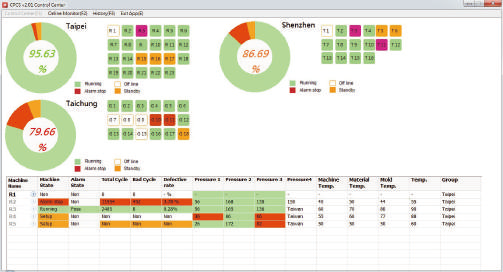

Cyberlink IMC software

Cloud monitoring software can easily integrate each factory information,through multiple graphs and information, provide production analysis, production efficiency assessment and machine usage condition.

In addition to this can also be a single machine for historical production history analysis. Suitable for quality highly anticipated, requiring the production process to be transparent and the best solution for standardization and the need for immediate management of production enterprises.

.Through the handheld device or computer monitoring and parameter modification

.The practical dashboard display shows all the key values at the a glance

.Easy to deploy production capacity, Control machine usage

.History data checking all the time, easy to analysis problem of production.

Controller

|

TM 410 |

TM 810 |

|

TaskMaster Controller |

||

|

Model |

TM 410 |

TM 810 |

|

Support QTY of Modules |

4 set |

8 set |

|

Operating temperature range |

-40 °C - 70 °C |

|

|

Size |

120.6 x 142 x 180 mm |

120.6 x 142 x 272 mm |

|

Weight |

2.12 kg |

2.82 kg |

|

Interface |

USB & EtherNet |

|

|

Support flash drive access |

Yes |

|

Pressure sensor

.png)

|

Model |

Rated capacity |

ΦA |

ΦB |

Natural frequency (Hz)

|

Rated displacement

(reference values)

|

Weight

(g,approx.)

|

|

CPS0720MS |

196.1 N

(20 kgf)

|

7 |

2 |

67000 |

0.003 |

2 |

|

CPS0750MS |

490.3 N

(50 kgf)

|

7 |

2 |

62000 |

0.005 |

2 |

|

CPS10100MS |

980.7 N

(100 kgf)

|

10 |

3 |

85000 |

0.005 |

3 |

|

Rated capacity |

196.1N (20kgf), 490.3N (50kgf), 980.7N (100kgf) |

|

Ultimate overload |

150 % R.C. |

|

Safe overload |

200 % R.C. |

|

Non-linearity |

1 % R.O. |

|

Hysteresis |

1 % R.O. |

|

Repeatability |

1 % R.O. |

|

Temperature compensation range |

-10℃ to 50℃ |

|

Safe temperature range |

-20℃ to 150℃ |

|

Temperature effect on zero balance |

1 % R.O./ 10℃ |

|

Temperature effect on output |

1 % LOAD/ 10℃ |

|

Cable |

1.0mm diia., 4-core shieided, 1.2m long,

direct end connectors

|

|

Minimum cable bending radius |

5mm |

|

Protection class |

IP64 |

|

Element material |

HRC42 stainless steel alloy or better |

|

Fatigue life |

1 million cycles with rated load |

Module

|

|

Model |

TC MCP4

(Mold cavity pressure module)

|

|

Channels of Qty. |

4 |

|

|

Max sampling rate pre channels |

50000 point/ sec/ ch |

|

|

Accuracy |

0/1 % F.S |

|

|

Operating temperature range |

-40℃ ~ 70℃ |

|

|

Model |

TC MCT4

(Mold temperature module)

|

|

Channels of Qty. |

4 |

|

|

Max sampling rate pre channels |

3 point/ sec/ ch |

|

|

Accuracy |

0/1 % F.S |

|

|

Operating temperature range |

-40℃ ~ 70℃ |

|

|

Model |

TM DIO8

( I/O control module )

|

|

Channels of Qty. |

8

(4 input, 4 output) |

|

|

Level of Voltage |

12V or 24V |

|

|

Input response time |

7 ms |

|

|

output response time |

500 ms |

|

|

Operating temperature range |

-40℃ ~ 70℃ |

|

|

Model |

TM AO8

( Voltage output module )

|

|

Channels of Qty. |

8 |

|

|

output range |

0~5Vdc |

|

|

Accuracy |

0.014Vdc |

|

|

Operating temperature range |

-40℃ ~ 70℃ |